The results are from an unpublished draft from Michael Katzler, who writes his thesis on this.

The "official" torque is 9 Nm. As I posted before until now I could not find the reason for this low torque, which - according to material values - should be about 15 Nm.

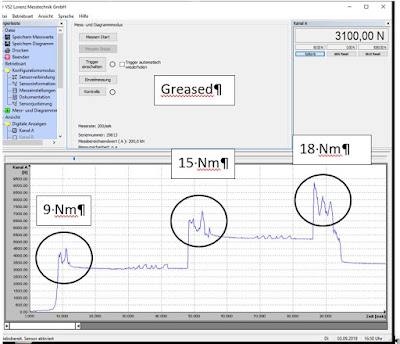

This is how tested it:

The difference between not greased and greased screws is significant:

The slipping force is less than half if you do not grease.

I tested with different torque:9 Nm, 15 Nm, 18 Nm.

It is obvious: The higher the torque the higher the slipping force.

But: How high can it be?

According to the standard the material must be minimum quality 5.8.

If you apply a torque of 35 Nm you may destroy the screw. Using 40 Nm you destroy it for sure.

Using a torque of 18 Nm is about half of the breaking load which is below the elastic limit.

Here is the comparison between greased and not greased, and different torque

9 Nm, 15 Nm, 18 Nm.

Here are the numbers:

Conclusion:

It is important to apply grease before using cable clamps, and if not, have a higher torque.

The best results are applying 18 Nm and apply grease.

Keine Kommentare:

Kommentar veröffentlichen